In this article, you will read about handrail systems regulations, examples of implementations, and the installation method using Special RBMs. You can also find more information about the McNetiq Setter Apparatus, the testing tool, and the benefits of using McNetiq RBMs.

Purpose, regulations, and implementations of the temporary handrail

Industrial temporary handrail or guardrail is, first and foremost, a passive fall prevention method for people and vehicles intended to prevent falls or unauthorized access to certain areas. Also, the system functions as mobility assistance.

OSHA and International Building Code IBC made even stricter rules and regulations regarding safety measures.

“Guardrails are required when the building has steps, landings, platforms or accessible roof spaces. According to the code, guardrails are required when there is a difference of 30 in. or greater between two upper and lower surfaces.”

OSHA, IBC.

According to the Dutch Working Conditions Decree,

“When carrying out work where there is a risk of falling, a safe scaffolding, rack, platform or work floor must be installed, if possible, or the danger should be counteracted by installing effective fences, railings or other such facilities.”

Arbeidsomstandighedenbesluit 3.16 Risk of falling.

Furthermore, the Dutch Building Decree, in their article 2.18 Height after 2003, announced:

“The general requirement for the minimum height of a required floor partition is 1 m by virtue of the first paragraph. In the event of a height difference between a floor and an adjacent floor, terrain or water of more than 13 m is the second paragraph requires a floor partition with a height of at least 1.2 m.”

Bouwbesluit.

A temporary Handrail system can be installed, for example, on a ship deck, storage tanks, stairs or bridges during construction works.

Temporarily handrail installation and structural load capacity of the design.

Handrail system installation should be in accordance with the imposed regulations. Your company should be responsible for providing a 100% safe workplace for the workers.

One of the most critical aspects of safety is knowing the handrail ability to withstand the probable forces. Suppose the structure is not strong enough against the stress or not installed adequately. In that case, that might cause the handrail to break and leave the person in a dangerous situation.

Temporary handrail installation using magnets

McNetiq RBM for temporary handrail

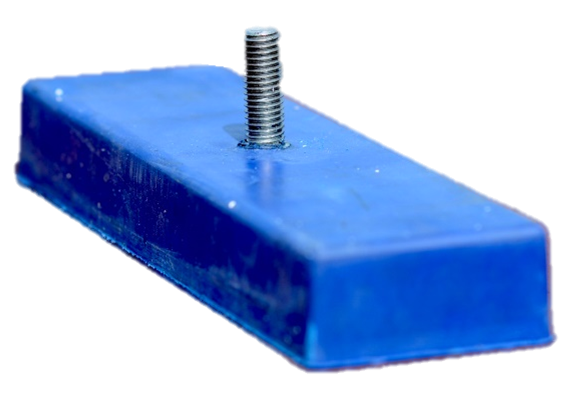

Generally, handrail systems are installed using drilled and bolded connections or welded connections. However, the mentioned methods can damage the counter surface. In some situations, damaging the surface or applying heat to weld the metal is not possible. Therefore, using magnets as a fastening method is a safe alternative solution.

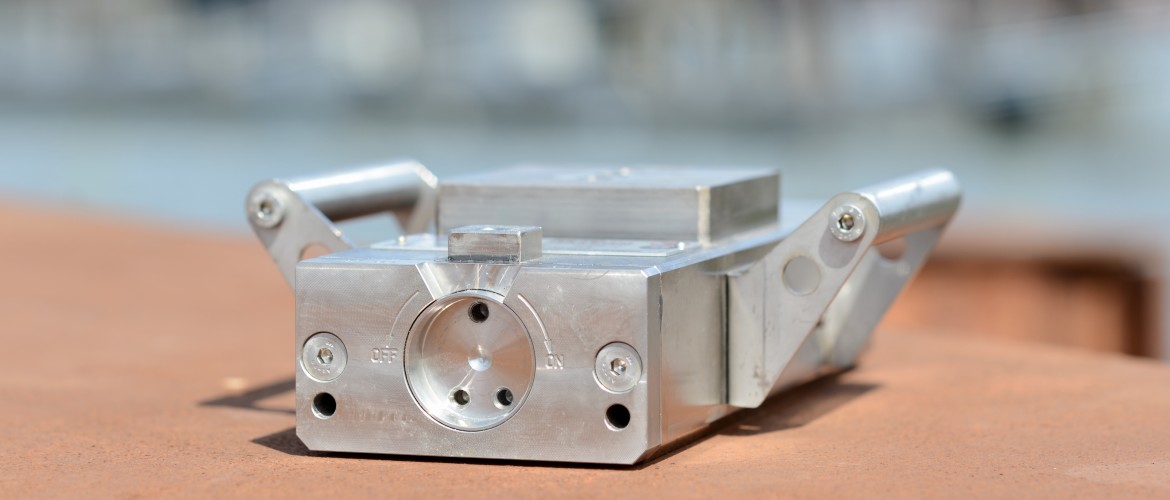

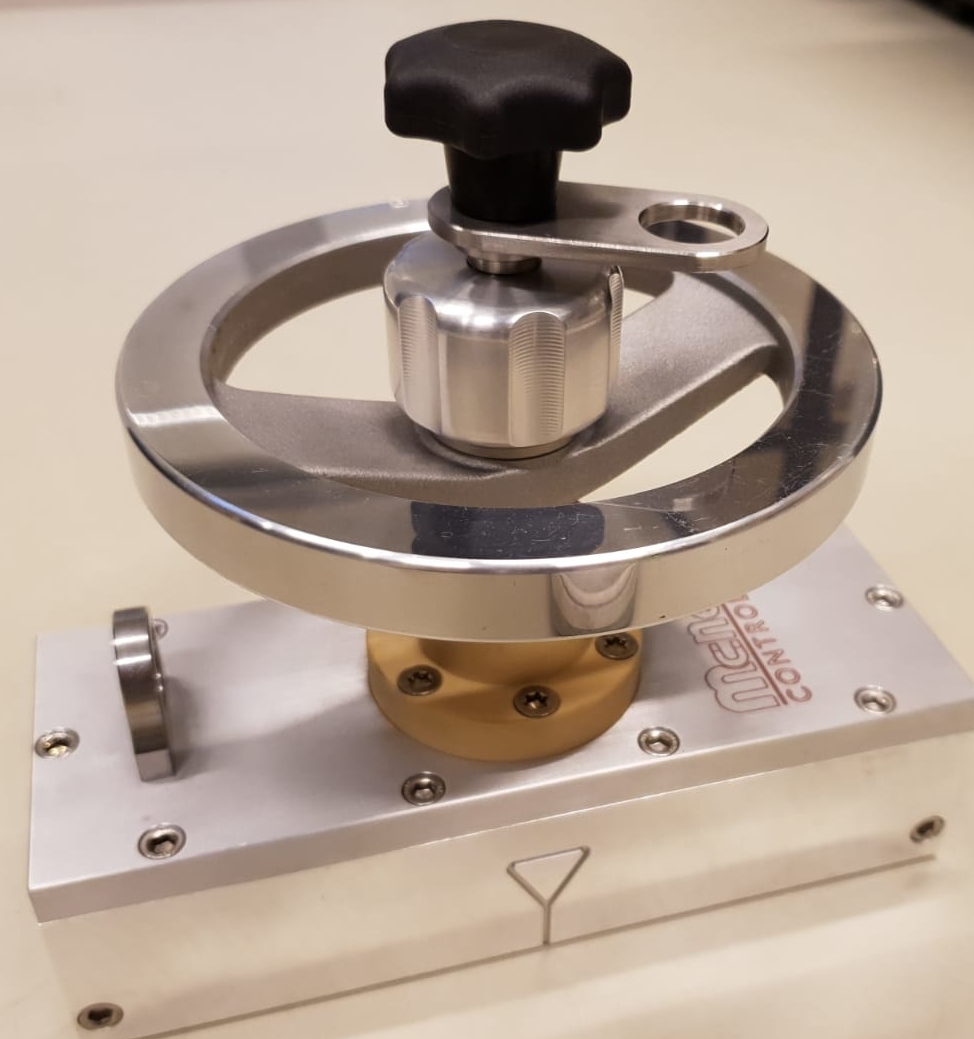

Rubber block magnet RBM with McNetiq setter apparatus and testing tool.

Mcnetiq RBM installer for temporary handrail

The RBM can replace conventional fastening methods. However, installing and uninstalling the RBM required skilled and experienced personnel. Therefore, McNetiq came up with a solution to make mounting and dismounting this special magnet safe, easy, and accurate.

McNetiq designed an installation tool to curry the magnet from the box and install it in the right place and at the exact position, and vice versa. Furthermore, a testing tool is developed to measure the exact capacity of the magnet. The firm received many awards for this technology.

Furthermore, Based on the Contrlock®, the organisation developed many applications, such as the Scaffold Anchor, Pipe Support, Fall Arrest, and Temporary handrail.

Knowing the design load capacity is a great advantage. It allows you to determine the amount of stress the handrail can take before it breaks. The magnetic force of McNetiq RBMs is up to 400kgf on untreated steel. The tested pulling force is 350kgf on 12mm steel with 0.2mm paint. The tested shear force is 250kg on 12mm steel with 0.2mm paint. For the manual, please fill in the form below.

The benefits of using the RBM with McNetiq technology are:

- Fast and flexible mounting and dismounting.

- Increase in safety.

- Save time.

- 0 damage to the counter surface.

- 100% accuracy of the load capacity.

Please bear in mind that special training (one day) is mandatory to adequately install and test the magnet capacity.

Following procedures and complying with rules will keep your people from harm and protect your business in the long run. Hence, safety precautions are a must. Furthermore, dealing with magnetic materials, installing, and testing them, requires a certain level of knowledge, which our specialists at McNetiq or our partner STE can provide.

To learn more about our Temporary Handrail System.

Please call us on +31 (0)85 130 45 66

Email us info@mcnetiq.nl

Or fill in the form below.