Mandatory safety standards vary by geographical region and application. Please contact us to discuss your intended use.

Fall Protection Certification Pending

Certification Pending

Falling from heights is the most occurring cause of fatal occupational accidents. From the ~2.3 million global work-related fatalities per year, it is estimated that 27% are caused by falls.

Legislators demand safety precautions. Mandatory fall protection is required when working at the height of more than 1.2 to 2.5 meters (or 4-8 feet), depending on circumstances.

There are two basic types of active Fall Protection:

- Fall Arrest, which stops a worker in the process of a fall

- Fall Restraint, which prevents a worker from reaching an edge

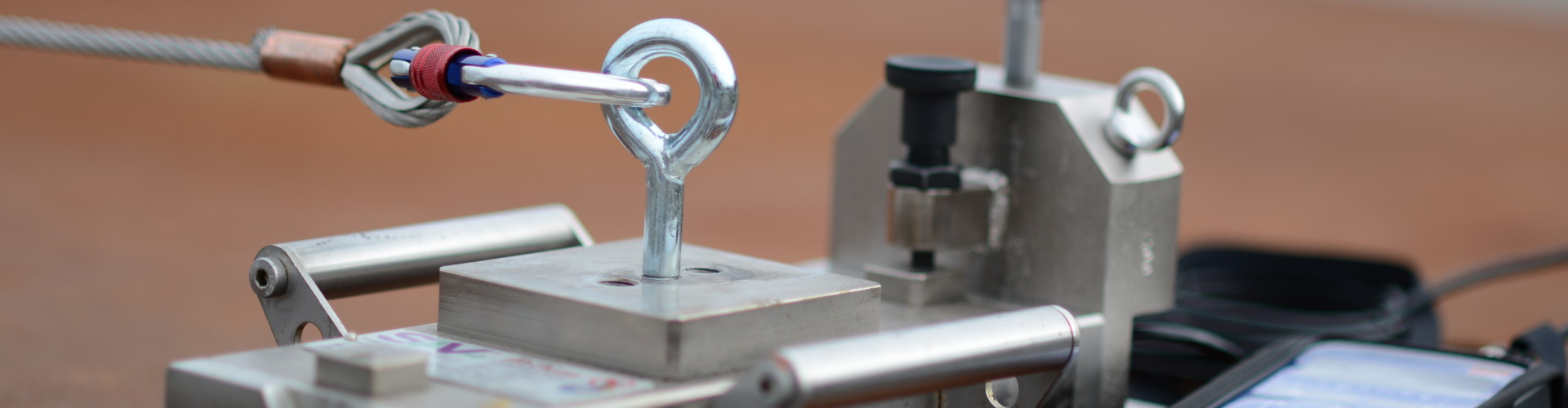

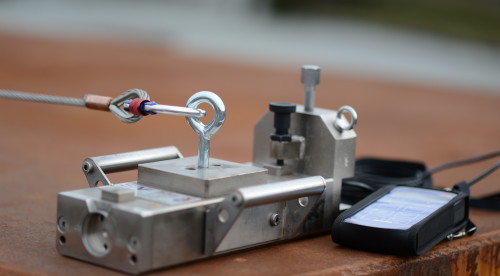

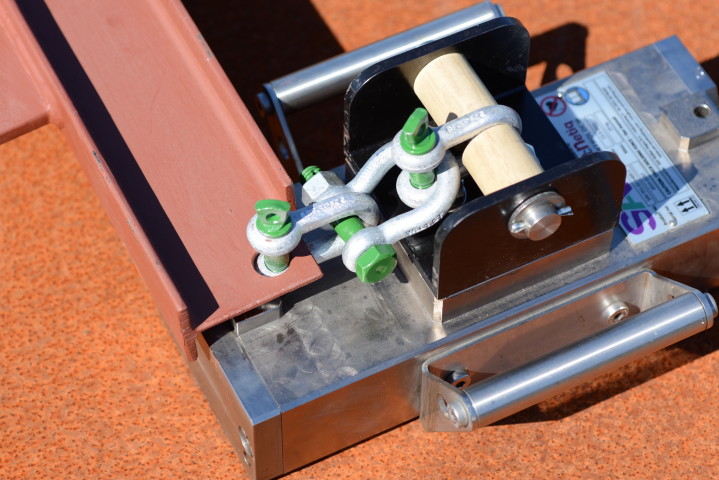

In circumstances where, for example, hand railings cannot be installed, then McNetiq magnets with Controlock® technology can be attached to lines to form a safe and secure basis for fall restraint purposes. McNetiq Fall Restraint System is based on using magnets that are connected to a lanyard with a harness to prevent the worker from reaching unsafe areas.

The McNetiq Fall Restraint System is complying with EN795 type B.

Working safely with magnetic anchors

With McNetiq magnetic anchors, fall restraint positioning lines can be safely secured. This technique is especially of value in situations where permanent fixing points cannot be used.

For safe use, it is critical to assess the magnetic strength of the anchor magnet: the thickness of the steel plate, coatings or paints, and uneven surfaces can influence the magnetic force. McNetiq’s patented Controlock® technology allows the users to check this strength on the spot.

McNetiq supplies magnetic solutions with Controlock® technology since 2013, initially for connecting scaffoldings to steel storage tanks. Users are global contractors that are serving a large range of the most reputable global independent tank storage operators, mayor oil producers, and chemical producers.

Examples of use

Offshore

Ship construction and repair

For the safe installation of handrails, welding, grinding, applying coatings and paint, inspection works, using of blowtorches, and preparation activities.

Containers

Working in vessel holds or hatch covers

Construction cranes, harbor cranes, and loading/unloading bridge cranes

How to use a magnetic anchor?

Manuals and training programs are typically customized for the specific use, or a standard McNetiq template is applied.