How to use a magnetic scaffold anchor point

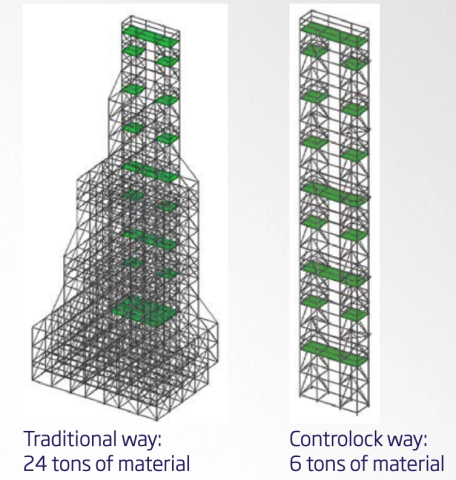

Based on the pre-defined design, the scaffold is built on site.

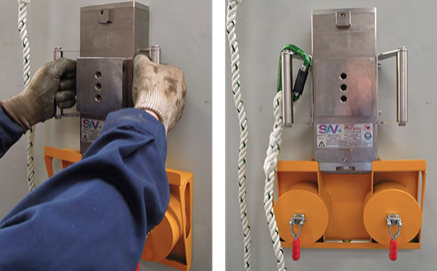

While the scaffold components are being installed, a certified Controlock® operator can apply the magnetic anchors. The operator can position the magnetic anchor and measure the actual pull and shear force of it at that location. If the operator determines that the readings are meeting the minimum required magnetic forces, that are specified in the design, then he can secure and clear the magnetic anchor to connect the scaffold.

This process should be repeated for every magnetic anchor.