Fall Protection Made Simple and Secure

Working at height requires reliable fall protection — it's not just essential, it's legally mandatory. Yet every year, accidents happen due to missing anchor points or the incorrect use of safety systems. While regulations demand that employers take proper safety measures, finding practical solutions on-site can be a real challenge.

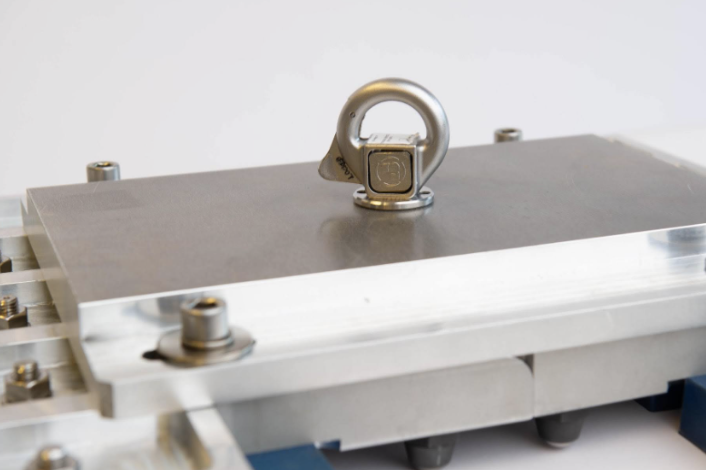

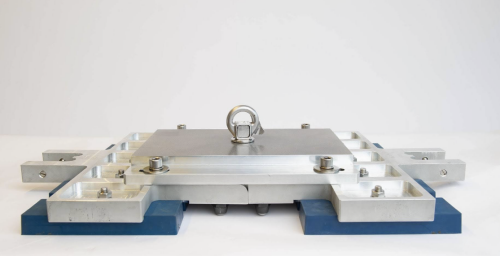

McNetiq’s magnetic anchors provide a smart, safe alternative:

- No drilling or welding – Preserve the integrity of your work surface.

- On-the-spot safety check – Controlock® technology allows instant verification of magnetic holding force.

- Flexible and reusable – Easily reposition anchors across multiple projects.

- Strong and secure hold – Reliable performance, even under tough conditions like vibration.