Magnets are used in the industry for a long time, but knowing the magnet’s capacity was not possible until McNetiq B.V. introduced the innovative Controlock magnet and the testing system, the Controlock® magnet anchor.

In this article, you will read about

- What is Controlock® magnet anchor?

- Cutting-edge approach

- Benefits

- Permanent magnets

What is the Controlock® magnet anchor?

In 2014 Bas Gravendeel and Edwin van der Heide established McNetiq B.V. to promote the Controlock® magnet anchor technology.

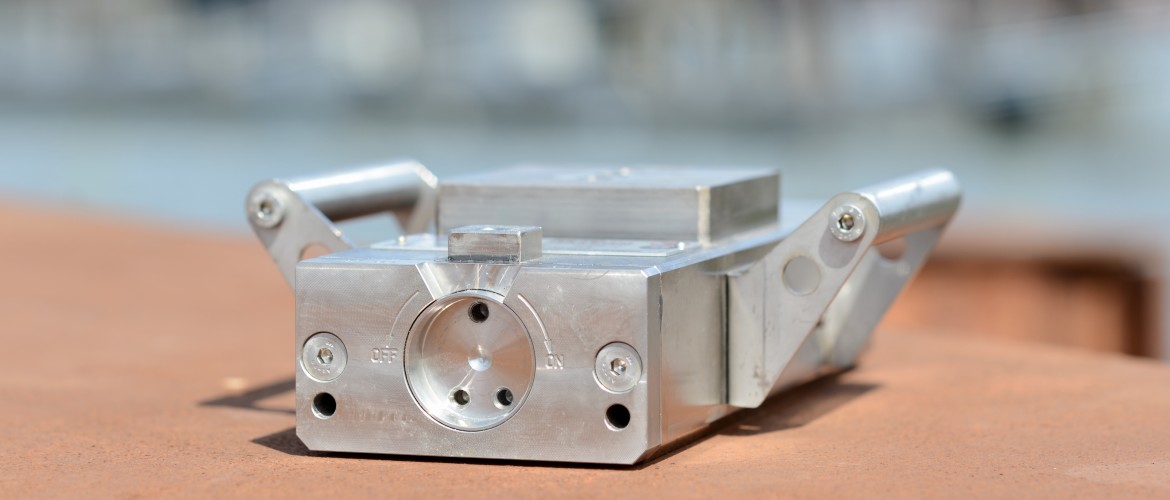

Controlock® is a magnetic scaffold anchor that replaces temporary steel connections in the industrial and marine fields.

The system measures the adhesive force of the used magnet with 100% accuracy, making it possible for the first time to determine the magnetic capacity. Controlock® anchor is, therefore, certified by DIBT, Dekra, and Lloyds, among others. Besides, the firm received many awards for this technology.

Cutting-edge approach

Compared to traditional steel connections such as drilling and welding, scaffolds built with Controlock® are constructed against steel walls such as storage tanks and ships without the need to use welding or a large abutment base to stabilize the scaffold.

Benefits

When you use the magnets to support your scaffold, you will reduce the materials used to construct the structure, and you will minimize the logistics footprint. Also, you will scale down the building time and decrease the needed workforce. Therefore, the system is

- More sustainable

- Safer

- And cost-efficient

The mentioned advantages encourage scaffolding companies to switch to using magnets. Furthermore, Based on the Contrlock®, the firm developed many applications, such as the Scaffold Anchor, Pipe Support, Fall Arrest, and Temporary handrail.

“With McNetiq Controlock® anchor, a scaffold can indeed be securely anchored: lean and mean, only where required. The result: savings of 40% on lead time and 70% on materials.”

Shell Rotterdam, November 2016.

Permanent magnets

The Controlock magnet anchor’s main component is neodymium, which means permanent magnets, with the ability to be turned on and off manually.

The benefit of using permanent magnets as temporary steel connections is that they don’t need an external source of power, which makes permanent magnets safer compared to electromagnets. Electromagnets are always dependent on a constant external power source to function. If this magnet’s power source is lost or the connection fails, this can have catastrophic consequences. For the manual, please fill in the form below.

To know more

Please call us on +31 (0)85 130 45 66

Email us info@mcnetiq.nl

Or fill in the form below